MEC can assist you with inspection services at many stages of an item of equipment's life cycle including fabrication inspection, commissioning inspection, in-service inspection and repair or alteration inspection.

MEC CAN OFFER INSPECTION SERVICES FOR THE FOLLOWING EQUIPMENT:

Pressure Equipment including (Coming Soon)

Boilers such as fire tube boilers, water tube boilers, hot water boilers

Pressure vessels such as air receivers, refrigeration plant, autoclaves, timber treatment vessels and process vessels

Pressure piping

Cranes and Lifting Equipment including (Coming Soon)

Mobile cranes with either telescopic or lattice booms including truck mounted cranes, all-terrain cranes, crawler cranes, telehandlers and container handlers from manufacturers such as Grove Manitowoc, Liebherr, Terex, IHI, P&H Kobelco, Kato, Franna, Manitou, Merlo, Dieci, Hyster

Vehicle mounted truck loader cranes of all brands like Palfinger, Hiab, Tadano, Unic, PM, Quicklift, HMF, Fassi, Cormach

Ships cranes/lifting appliances including pedestal mounted straight, knuckle and telescopic boom cranes, davits and derricks

Lifting equipment such as lifting beams, spreader bars, lifting attachments, pallet forks and man cages

Elevating Work Platforms including

Truck mounted EWPs (Bucket trucks)

Scissorlifts

Boom lift EWPs (Cherry pickers/Z booms)

Trailer mounted EWPs

All brands like Aichi, Versalift, Donghae, Isoli, Genie, Snorkel, JLG, SkyJack, Haulotte & Dingli

In-service inspection of these machines include 6 monthly inspections and major inspections.

6 monthly inspections include a thorough visual examination and testing of all functions and safety systems.

Major inspections require the stripping down and removal of critical components for a more detailed examination including non-destructive testing.

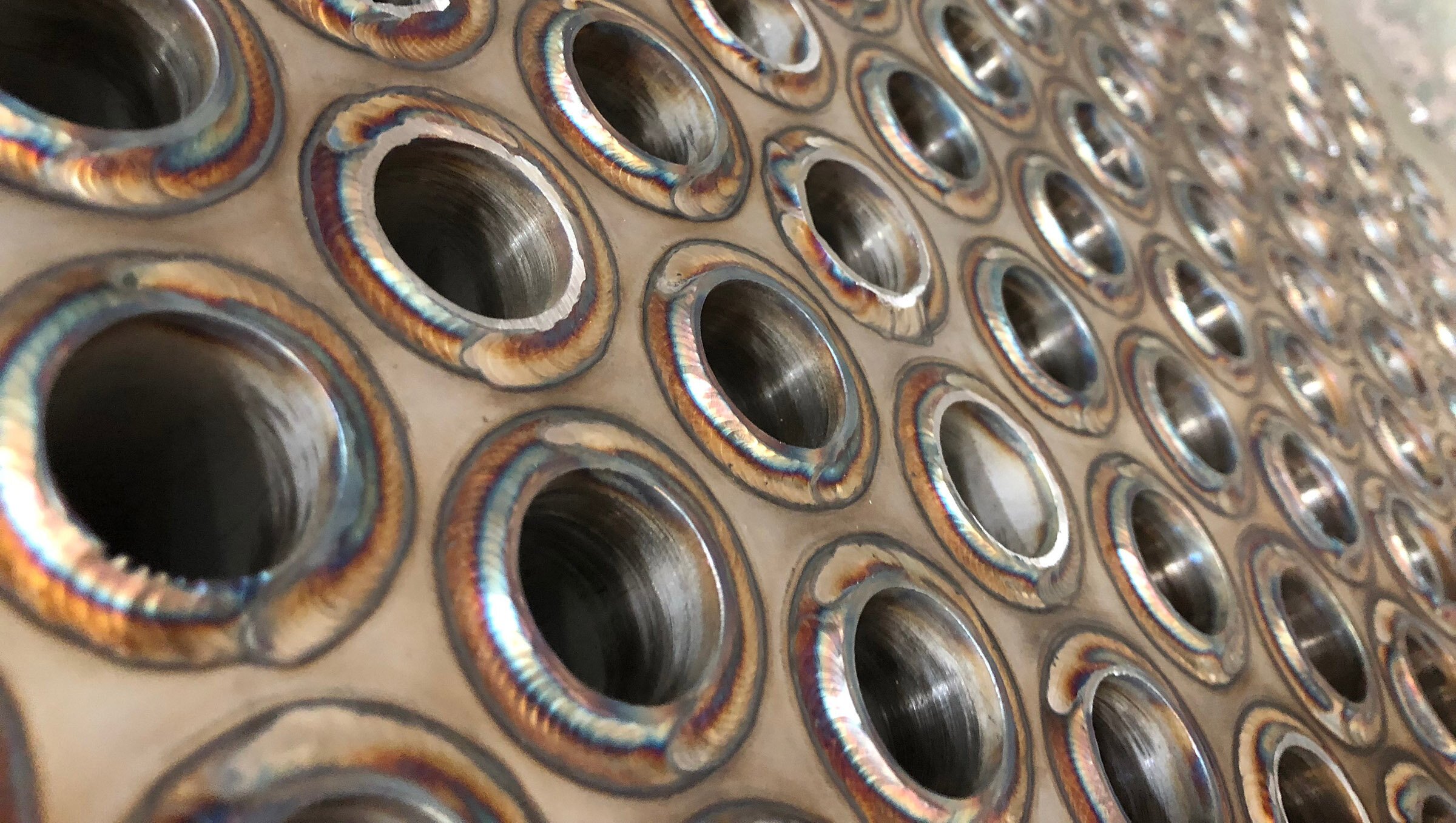

MEC have fully qualified and experienced welding inspectors and non-destructive testing technicians available. Whether you need a visual inspection, crack testing or thickness testing, MEC can provide a professional and efficient service.

OUR WELDING INSPECTION SERVICES INCLUDE:

Welder qualification testing to a variety of codes including ISO 9606 for steel structures, AS/NZS 1665 for aluminium structures and ASME IX for pressure piping etc.

Welding procedure qualification including testing and welding procedure specification development in accordance with a variety of welding codes including AS/NZS 1554 for steel structures, AS/NZS 1665 for aluminium structures and ASME IX for pressure piping etc.

We come to your premises to witness the welding so you can do what you do in familiar surroundings using the gear you know best.

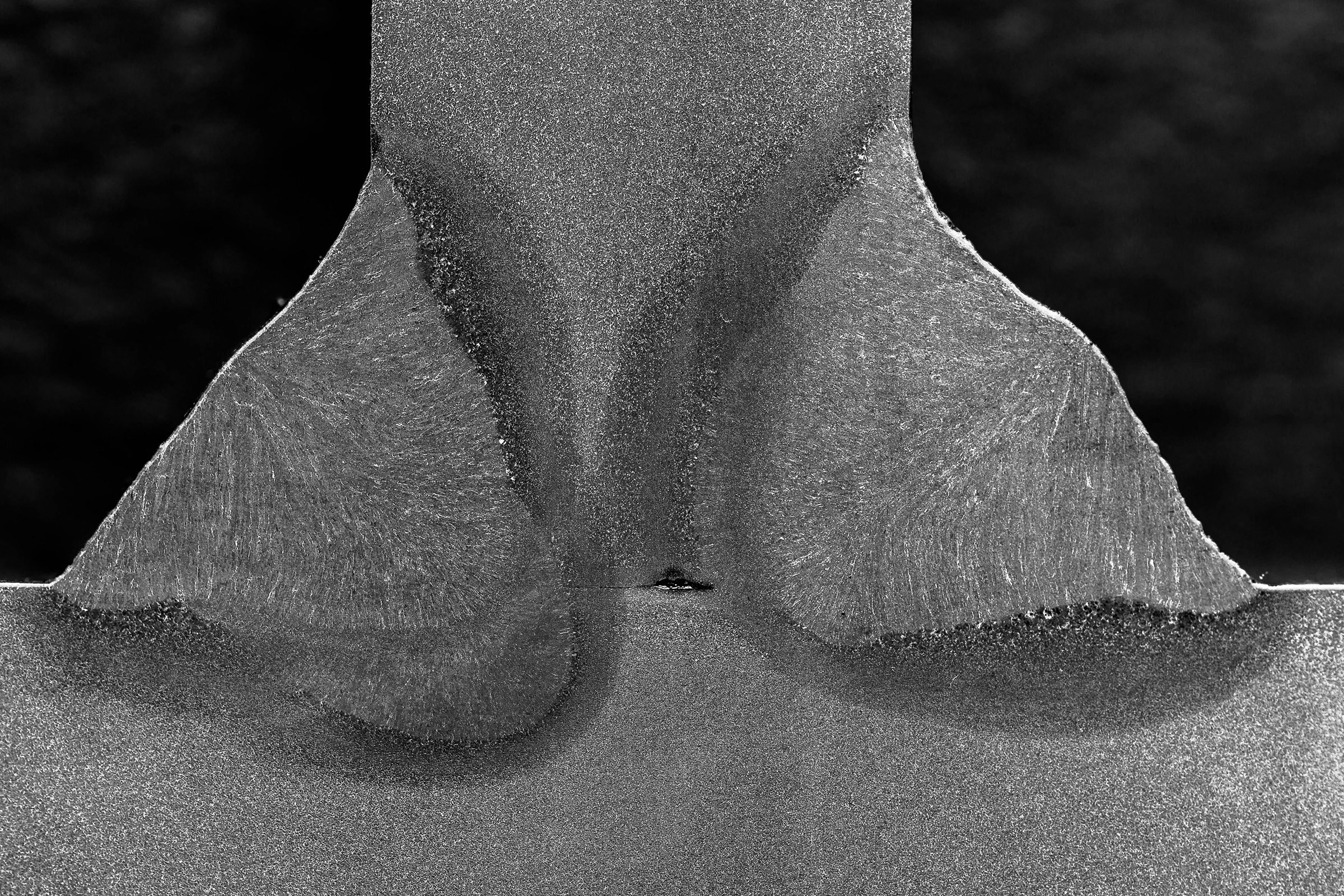

Mechanical / Destructive Testing in accordance with a range of method and welding codes. MEC can conduct mechanical / destructive testing of weld samples in-house or on site at the clients workshop including:

macroscopic examinations

bend testing

fracture/nick break testing

No more waiting for samples to be sent away for testing, get your results on the day!

Magnetic particle inspection for the detection of surface or near surface discontinuities in ferro magnetic materials. Generally used for crack testing of steel components, we can test in accordance with steel welding code acceptance criteria or to the clients specification for a variety of purposes. Quality control of welded structures as specified by the engineer and/or welding code, detection of cracks in suspected damaged components, verification of the successful removal of the crack prior to repair welding and verification of the quality of the finished repair weld after the specified post weld hold time and to check for delayed cracking.

MEC have a qualified ultrasonic thickness testing technician utilising the latest Olympus testing gear available for a variety of thickness testing projects such as ship hull thickness testing and timber treatment vessel shell thickness testing.